Our quality standard

Only the best is good enough for us

We want our special beers to be a source of pure enjoyment, and our high quality standards and the devotion of our brewers help us achieve this. And then you have the oldest piece of foodstuff legislation in the world: <link internal-link internen link im aktuellen>the Purity Law for beer. Since 1516, German beer may only be brewed with water, malt, and hops. Yeast, which is particularly important in the brewing process for turning sugar into alcohol, was not yet recognised as a separate ingredient at the time. Nevertheless, this is covered by this foodstuff ordinance, the only one of its kind in the world. And these days, in keeping with the principle of transparent consumer protection, the ordinance helps promote food safety and provides a guarantee that our beers too are natural, pure, and above all delicious products made from the best ingredients and will remain so. For our part, we make sure we abide by our own quality guidelines, which also support these objectives.

We buy from the region

To brew our special beers, we only use natural raw materials sourced mainly from suppliers based in our region: barley malt, wheat malt, water and hops. All the yeast we use to make our beer is grown by us alone.

We maintain an ongoing and fair dialogue with the partners we choose, and believe in long-term collaborations. All this helps ensure we meet our high quality standards.

A modern outlook to preserve the environment

To ensure we use raw and additional materials with great care, we implement modern and highly environmentally friendly technologies. Our success is based therefore on the way we go about our work, with the emphasis on both quality and what is good for the environment. And this is why we are constantly committed to raising the bar through innovative collaboration – both now and in future.

Our guidelines show us the way

Our quality policy is set out in our corporate guidelines, which form an integral part of our broader corporate policy. It applies to employees across all areas of the business.

In order for us to be both supplier and service provider for our customers – and also cope with increasingly complex production and administration processes – every employee needs to strive for top quality across all areas of our brewing family.

As part of the quality management system, we perform quality assurance for our products, the service we provide our customers, and our internal processes based on benchmarks set out in the DIN ISO 9000 series of standards.

A selection of our quality management measures

Checking the brewing or special malt in the brewhouse

Even before the malt is cupped for further processing in our silos, the masher draws the first malt samples from the truck. He inspects these samples in terms of smell, colour, and granularity and checks for signs of foreign seeds or other foreign bodies. This process is also known as manual inspection.

The employee compares the results of this inspection once more, with the details provided by the malt supplier. If the malt satisfies his – and therefore our – quality requirements, he will allow the truck to be unloaded. Further samples are also drawn, however, throughout the unloading process.

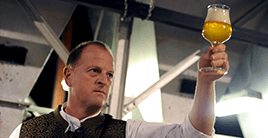

Sensory beer inspection

Before a brewed beer is released for filtration, our brewers subject it to a sensory quality inspection. Besides smell and flavour, particular attention is paid to the original gravity, cloudiness, pH value, bitter values, and natural carbonic acid content. By doing this, we ensure only the best beers undergo further processing and bottling.

The final acid test before sale

Following bottling, further product samples are taken in the bottle cellar. With the so-called forcing test, we try to establish the beer's shelf life. By creating extreme temperature fluctuations between 0°C and +60°C, we age the product samples artificially and review this process.

Together with a final sensory inspection concerned with original gravity, bitter units, colour, smell, foam stability, flavour, and so on, this is the last step before one of our beers heads off to our customers and beer lovers.