The brewing process

From the raw materials to the finished beer

For us, brewing is a traditional craft that deserves total devotion. The steps involved have remained essentially unchanged over the centuries – even though, of course, we perform them in accordance with the state of the art. But our special beers mainly owe their souls to the passion our employees dedicate to each individual step.

Mashing

The ground brewing malt is mixed with water. At various temperature levels, the enzymes in the malt convert the starch in the endosperm into maltose. At the same time, the soluble malt elements, like proteins and maltose, dissolve in the water.

Lautering

During lautering, the dissolved parts of the mash are separated from the solid, insoluble parts of the malt grain. The so-called wort is left over, and this provides the basis for the rest of the brewing process. The fruit and seed husks from the malt grain are put to profitable use as cattle feed.

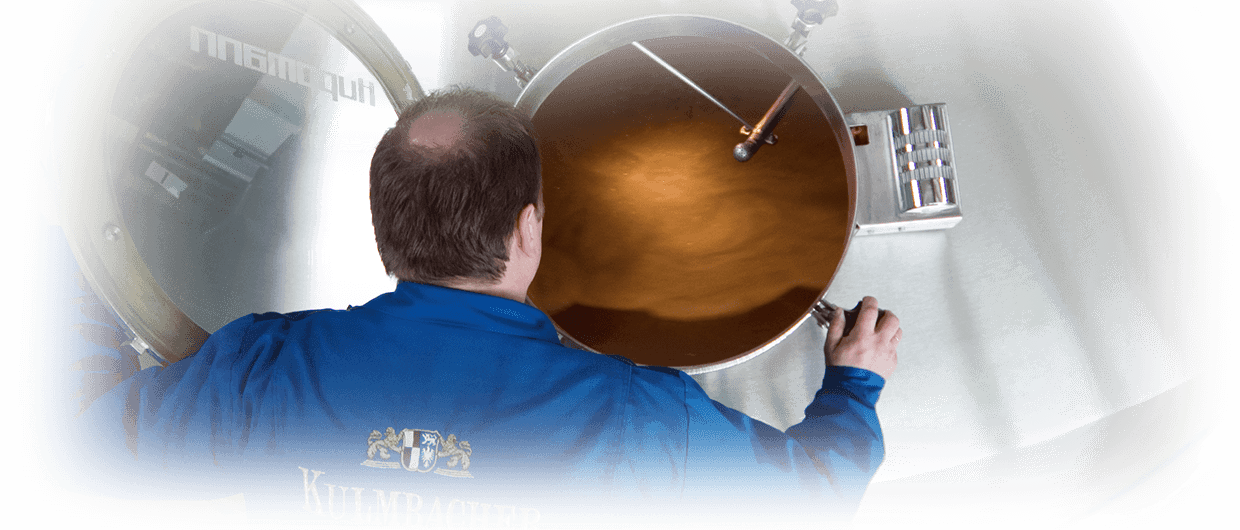

Wort boiling

Following lautering, the wort is boiled. The hops are added during boiling, and the bitters and aromatics from the hops are able to dissolve. The so-called soul of beer, hops are responsible – along with the malts used – for the ultimate flavour of our special beers.

Cooling

Following the boiling period, the whole wort is cooled to around 10°C. Yeast is then added to the cold wort, and this induces fermentation.

Fermentation

During fermentation, yeast converts the maltose in the wort into alcohol and carbonic acid.

Maturing and storage

Each beer needs its own maturing period to allow its full flavour to develop. All the breweries owned by Kulmbacher Brauerei Aktien-Gesellschaft place great value on this step and give their special beers the time they need.

Filtration

Following storage, the beer is fully mature and ready. With most types of beer, however, the yeast and any suspended solids are filtered out prior to bottling. This ensures the end product is crystal clear.